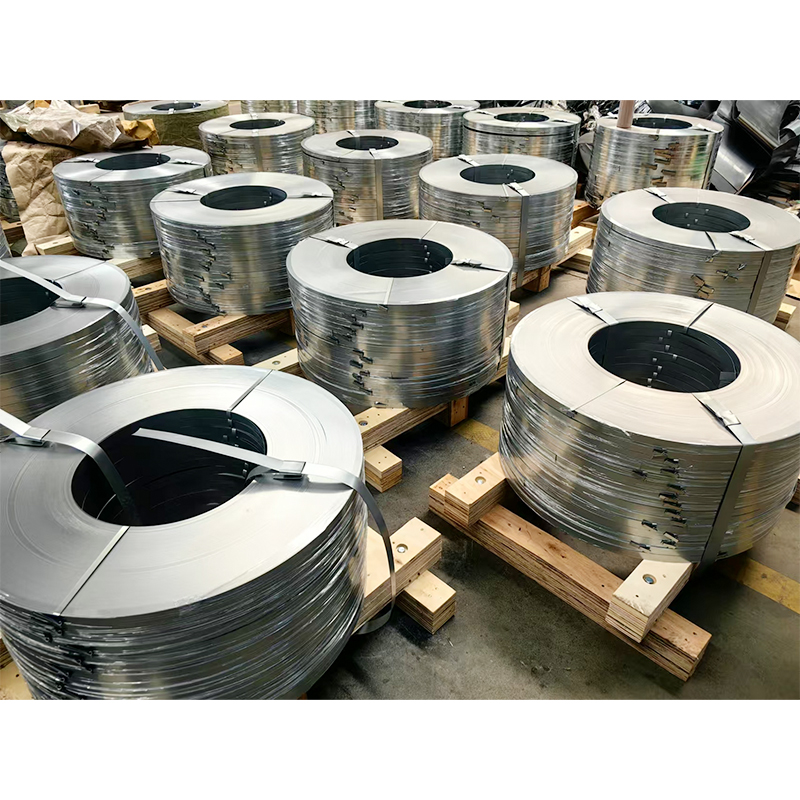

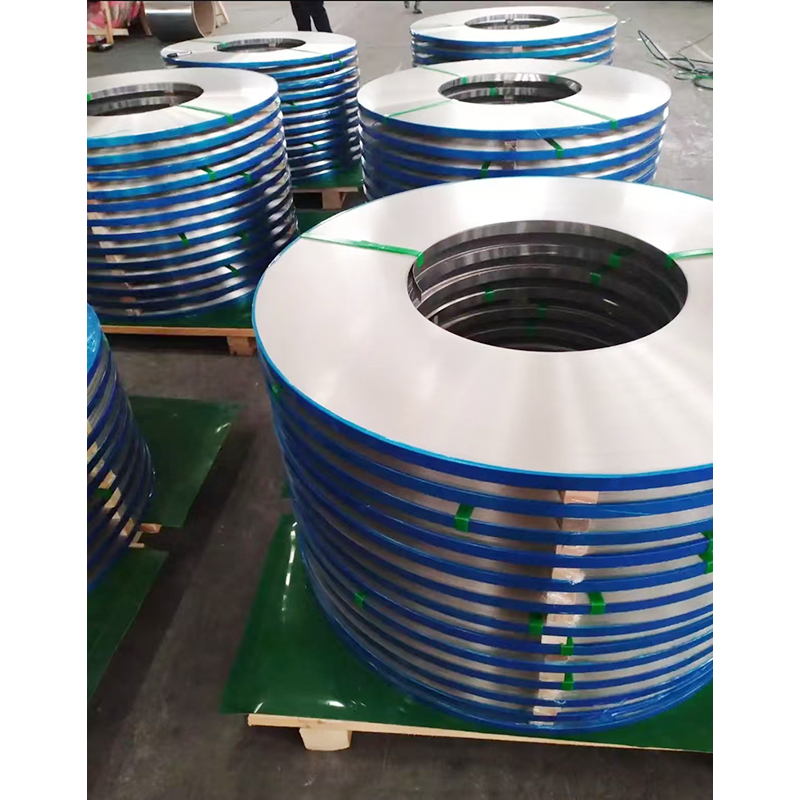

Among many types of steel, cold rolled coil, with its unique production process and microstructure, exhibits several significant advantages in processing and forming performance, making it the preferred substrate for high-precision, high-quality manufactu

- +86-13450612756

- 155203573@qq.com

- Room 101, No. 1 Chuncheng 9th Street, Tielukeng, Qishi Town, Dongguan City