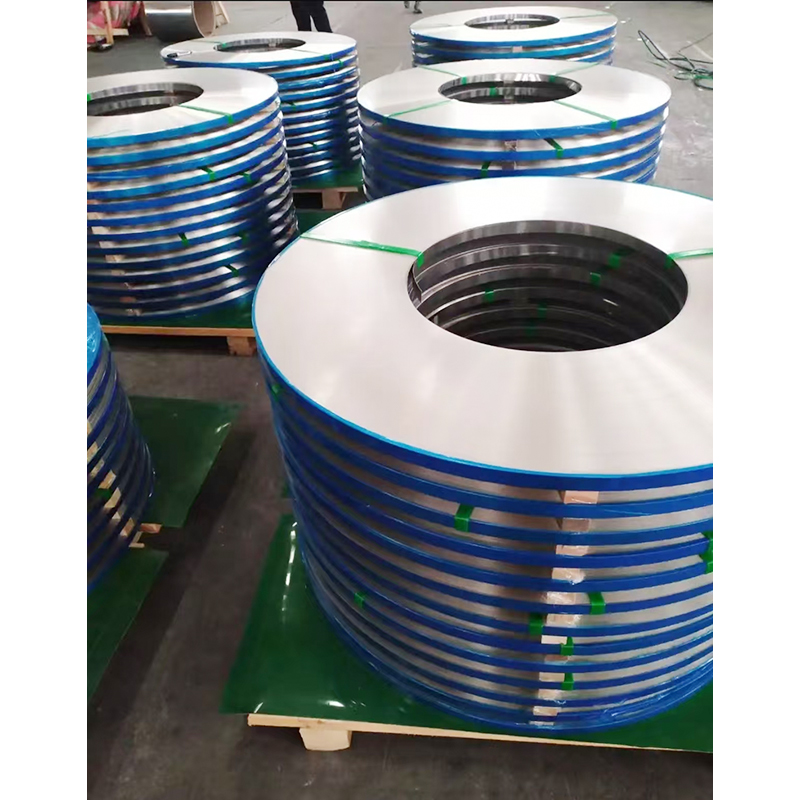

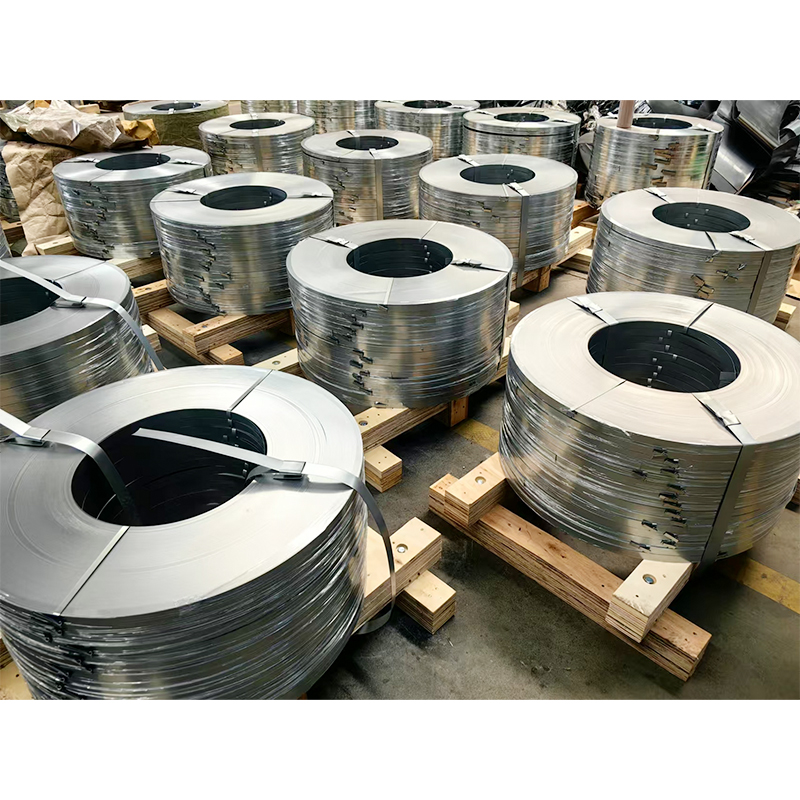

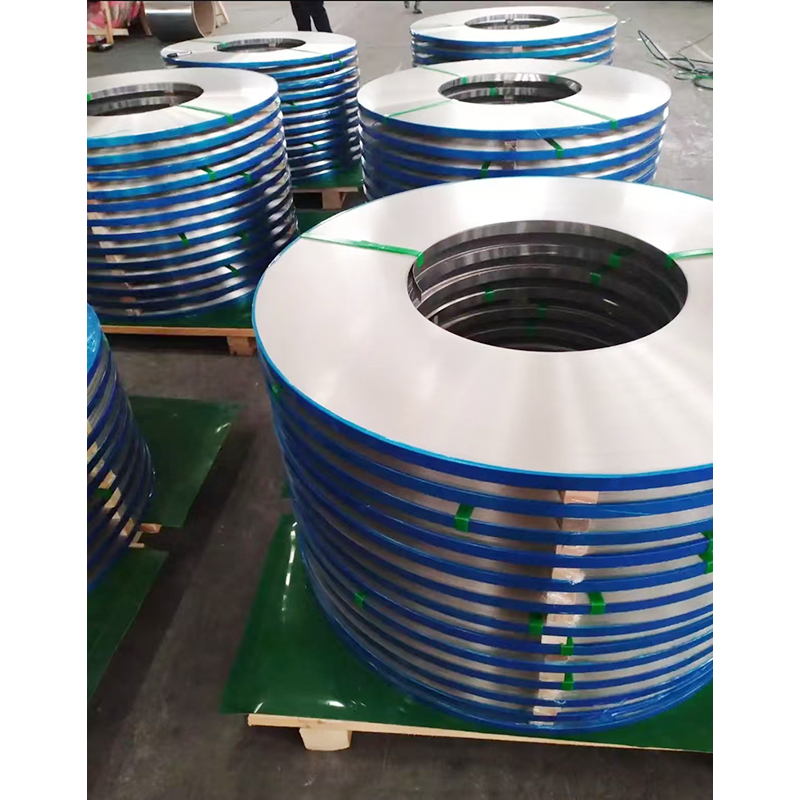

As an important form of supply, medium carbon steel coil often requires welding for component integration after stamping, shearing, and forming.

- +86-13450612756

- 155203573@qq.com

- Room 101, No. 1 Chuncheng 9th Street, Tielukeng, Qishi Town, Dongguan City