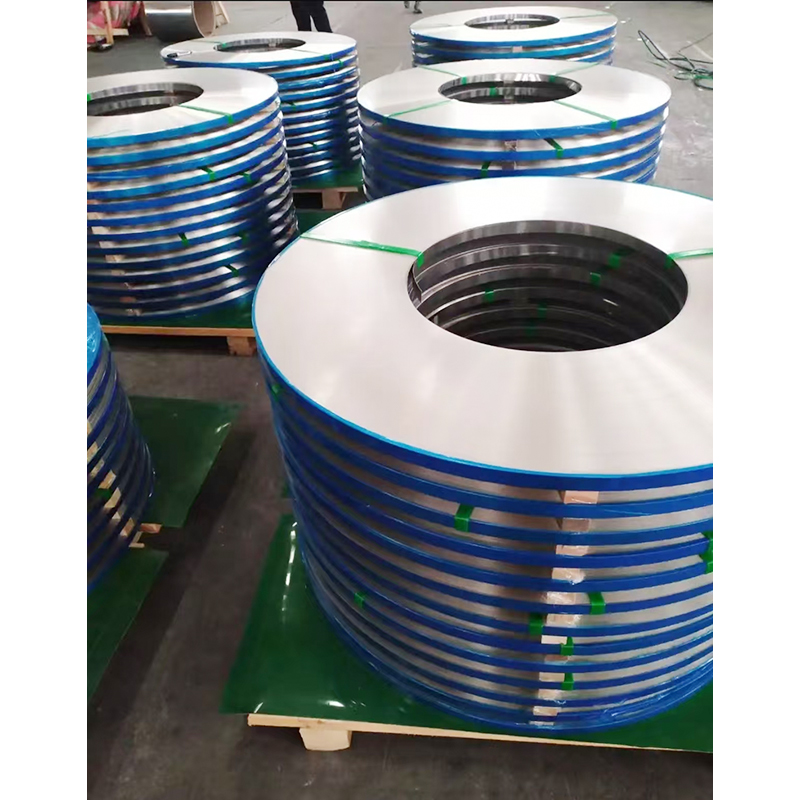

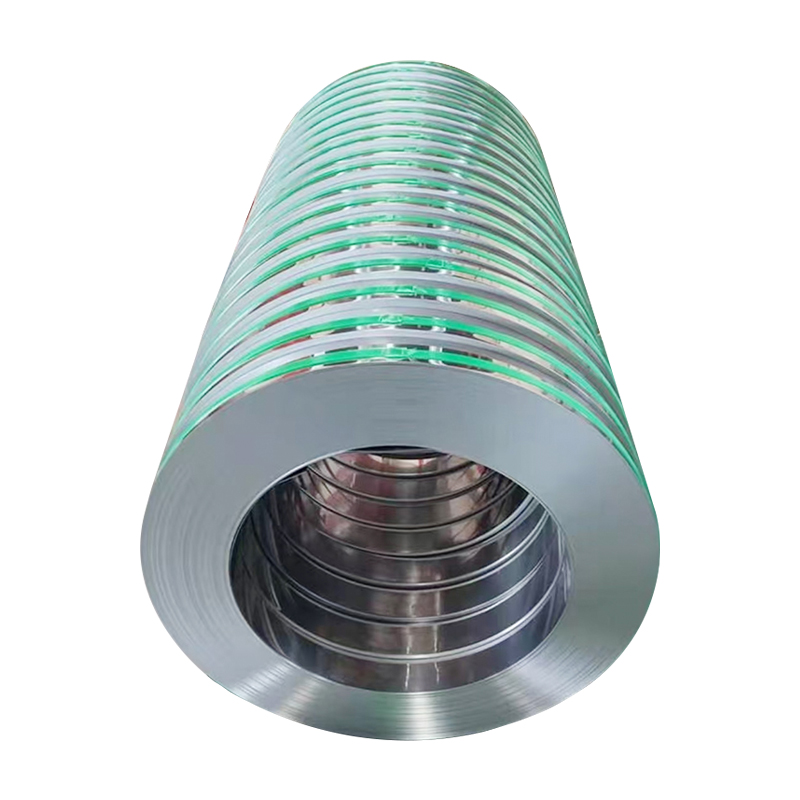

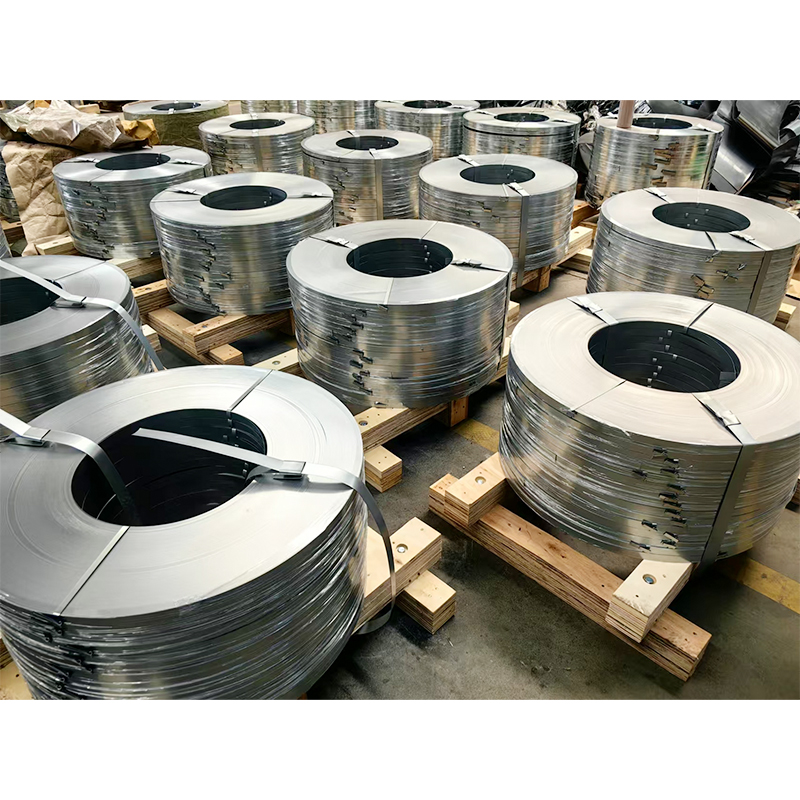

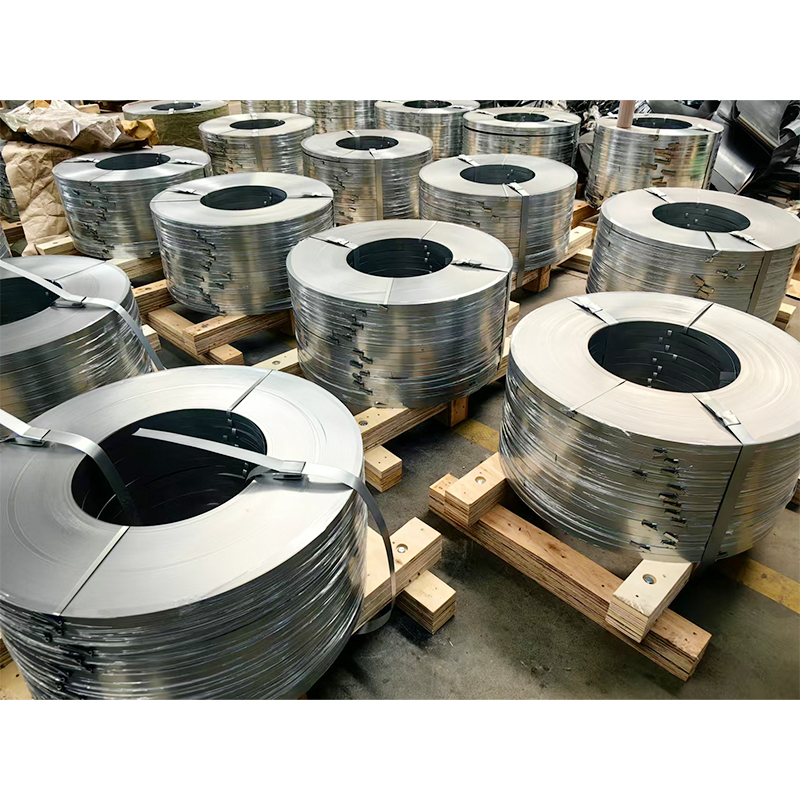

High-carbon steel coil, as a high-quality steel, with its exceptional mechanical properties and machinability, has become a key raw material for the manufacture of high-strength components, playing an irreplaceable supporting role in the industrial system

- +86-13450612756

- 155203573@qq.com

- Room 101, No. 1 Chuncheng 9th Street, Tielukeng, Qishi Town, Dongguan City